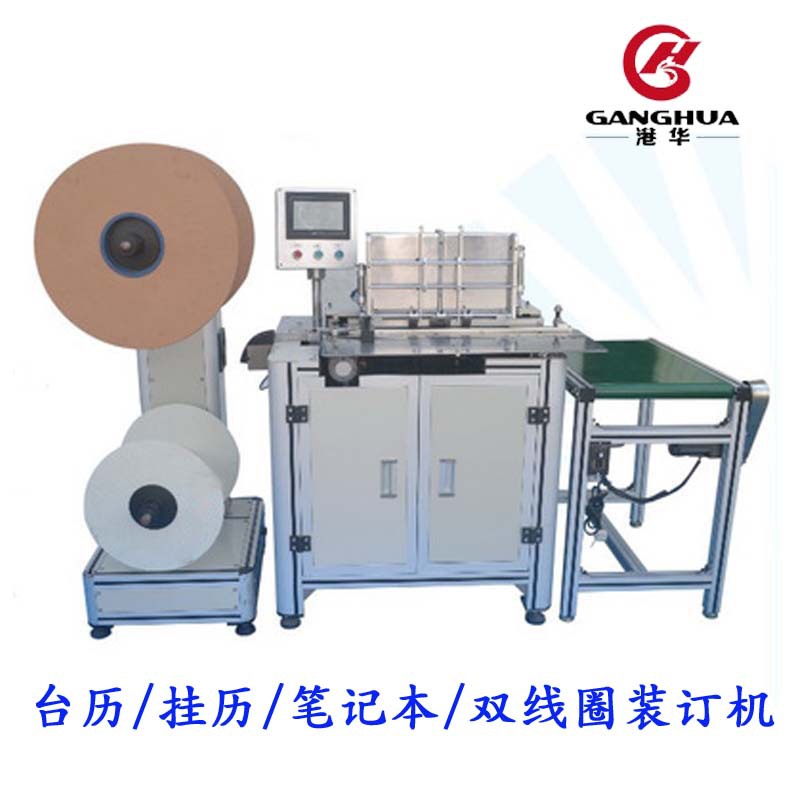

- 型号:DWC-520

- 名称:半自动双线圈装订机AUTOMATIC DOUBLE WIRE CLOSING MACHINE

- 品牌:港华装钉

- 包装:出口木箱

- 产地:东莞万江

- 外形尺寸:(mm)

- 净重:380(kg)

- 包装尺寸:1510x1050x1510(mm)

- 包装重量:530(kg)

型号 | Model | DWC-520 |

送件方式 | Feeding Model | 人工送件 |

装订方式 | Handing of Double Wire | 自动分段剪条、穿线及压合成型 |

可装订线圈规格 | Wire Specifications | 直径1/4”--7/8” |

齿距规格 | DistanceSpecification | 2:1、3:1 |

可装订书籍厚度 | BooksThickness | 3/16”--9/16” |

/(?:)/大纸张宽度(毫米) | Max.Paper Length(MM) | 520 |

/(?:)/大装订宽度(毫米) | Max.Binding Width(MM) | 507 |

/(?:)/小纸张宽度(毫米) | Min.Paper Length(MM) | 75 |

工作速度(次/小时) | Working Speed (Books/H) | 1200-2400 |

工作台尺寸(毫米) | Size of Work table(W×D)(MM) | 660x300 |

电源 | PowerSupply | 220V/1ph/50Hz |

空气压缩机(客户自备)千瓦 | Air Compressor(not included)(KW) | 1.5 |

气压(bar) | Air Pressure(bar) | 6-8 |

主机尺寸(宽x深x高)(毫米) | Machine Dimensions(W×D×H)(MM) | 1030x770x1200 |

主机重量(公斤) | Net Weight(excl .power pack)(KG) | 380 |

机器重量(公斤) | Net Weight(KG) | 530 |

放线架尺寸(宽*深*高)(毫米) | Dimension ofPy-off Unit(MM) | 490x760x1230 |

放线架重量(公斤) | Weight ofPy-off Unit(KG) | 65 |

安装占地空间(毫米) | SpaceInstalled(MM) | 1800x760x1230 |

出口木箱包装尺寸(毫米) | PackingDimensions forExport cases(MM) | 1510x1050x1510 |

自动装挂钩装置 | Automatic hanger attachment |

|

【产品说明】功能特点:此款装订机是采用日韩国际科技技术改造出在国内速度快,功能多独有的双线圈装订设备。本机广泛适用于笔记本、练习本、挂历、台历等活动页装订。本设备包括三部分:放线架、工作台(含挂钩装置)、传送带。集自动送线、剪条、输送、装订等步骤为一体,该机极大提高了生产效率,降低了生产成本。微电脑控制,可装订全部常规规格的线圈,尤其适合装订内外页不一致的本册。

1、操作方便简单、速度快、工作效率高,工作速度达800-2000本/每小时(具体速度视需装订本册的孔位是否方便对齐,如封面与内页页边缘不整齐或异型页面将会影响工作速度,和工人的熟练操作程度);

2、装订双线圈直径由1/4”--7/8”;

3、装订书籍厚度由3/16”--9/16” ;

4、装订书籍宽度70--520毫米;

5、线圈齿距由2:1, 3:1;

6、可另选自动装挂钩装置;

7、自动故障提示功能;

8、中英文画面,并可根据客户要求编辑各国语言;

9、自动收书功能,人工只需将书本放在工作台上,装订完后自动将书本输往输送带,提高生产效率。

10、本机重要动作元件改用新型滑轨型确保长寿命与稳定性;

【Description】Advantages:Features of the equipment: This binding machine is a double-coil binding equipment that is the fastest and most unique in China with the Japanese and Korean international technology. This machine is widely used in notebook, exercise book, calendar, desk calendar and other activity page binding. The distinguishing feature is that all conventional coils can be bound without changing the mold. The equipment consists of three parts: the pay-off stand, the work table (including the hook device), and the conveyor belt. It integrates the steps of automatic feeding, trimming, conveying and binding, which greatly improves production efficiency and reduces production costs. Microcomputer control, simple and fast operation. It can bind all the coils of normal specifications without changing the mold. It is especially suitable for binding inconsistencies between internal and external pages.

- 1. Easy touse, fast, and efficient, the working speed can reach 800 to 2000 per hour (the specific speed depends on whether the hole position of the book is convenient to be aligned, such as the cover and the inner page edge are not neat or the special page will be Will affect the speed of work, and the skilled operation of the workers).

2. Diameter of binding double coil is from1/4 " to7/8";

3. The bookbinding thickness is from3/16" to 9/16";

4.The width of the bookbinding is from75 to 520 mm;

5. Coil pitch:2:1, 3:1;

6. Customers can choose another automatichanger attachment;

7. Automatic fault prompt function;

8. Chinese and English characters display,can edited into various language according to user requirements;

9. It has the function of automatic book receiving, manual only need to put the book on the work table, after bookbinding automatic transfer of books to the conveyor belt, and it can improve productivity;

10.The important action components of this machine are changed to a new type of slide rail to ensure long life and stability